OUR SERVICES

At ARS, we offer integral railcar services for maintenance and repair, including blasting and painting, and new manufacturing. Our facilities are located in Moncton, which also enables us to offer car storage and transloading for effortless access to open-sea waters.

Transloading/reloading services

Moncton is a strategic location as the hub of Atlantic Canada, and is well-connected with deep water ports for international transportation. For this reason, our transloading and reloading services offer seamless transportation both nationwide and internationally. The 25-acre ARS yard is adjacent to CN’s 900-acre intermodal yard, which has direct access to CN’s main line.

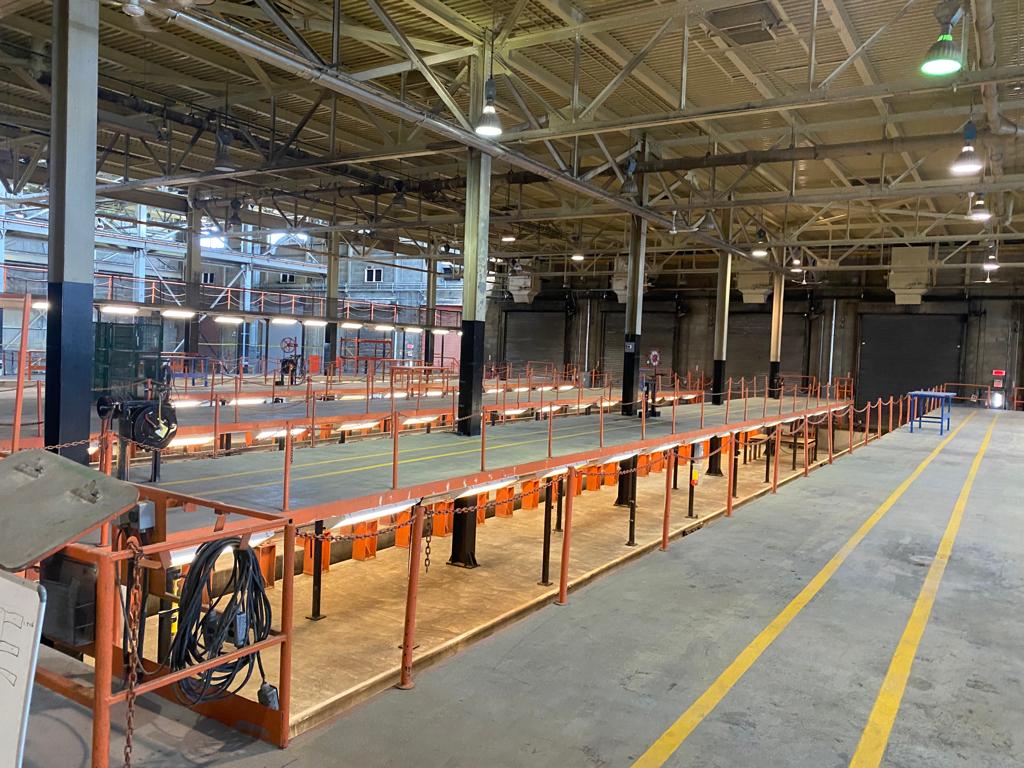

New manufacture & assembly

The plant is equipped with six run-through tracks for sequential railcar assembly and production, with highly skilled engineers and technicians. Our facilities can adapt to different car type production.

Maintenance & repairs

Whether it is scheduled, predictive or corrective, our facilities are equipped with designated workshop areas with multiple maintenance stations. Our expertise also includes wreck damage repairs in both structural and non-structural repairs under the strictest quality-control guidelines.

Blast & paint services

In ARS we have over 100,000 hours of painting completed in our blasting and painting booths. Also, we comply with environmental requirements and use recycled air to reduce operational costs.

Rolling stock modernization & upgrades

Our team has completed dozens of modernization projects to upgrade hundreds of railcars to provide years of serviceability. Our range of work encompasses all elements of car body and structure, interiors and electrical systems.

Fleet program modifications

ARS has completed fleet modification programs for EMD, CN, VIA Rail and other rail operators. Whether your requirements are plug and play modifications or engineering and design remodeling, we can deliver.

Car storage

As an industrial company, storage shortage is a common issue; ARS’s yard can accommodate 100 freight cars, which are at your disposal at any time.